Instruction:

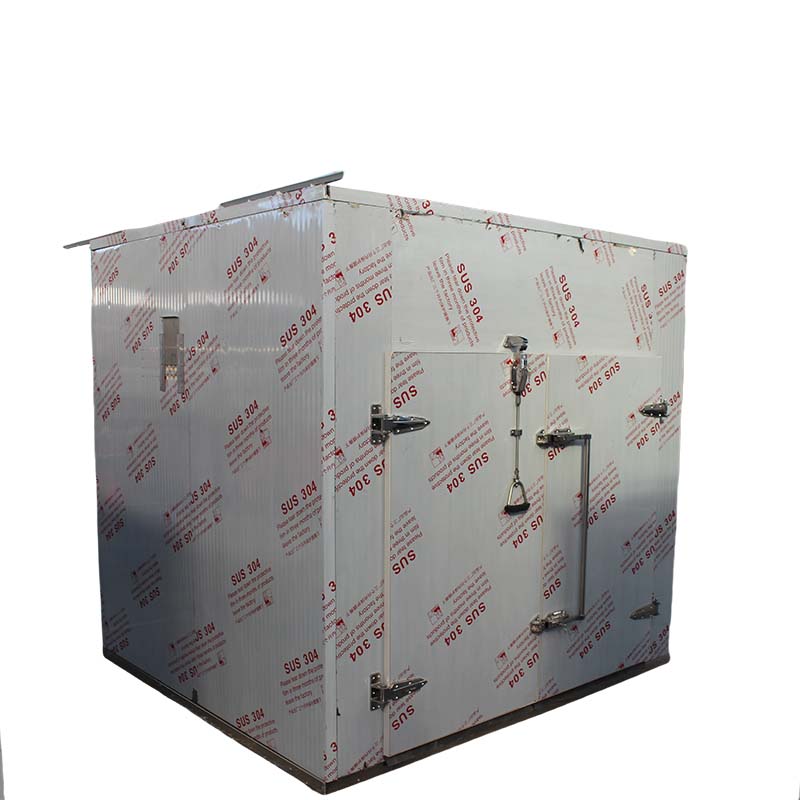

Box Body: Usually made of metal materials such as stainless steel or carbon steel, it has good sealing and thermal insulation performance, which can reduce heat loss and maintain a stable internal temperature. Common shapes are square and rectangular.

Heating System: It can use various methods such as electric heaters, gas burners, coal - fired hot air stoves, and air - source heat pumps to provide heat energy and heat the air to a set temperature.

Drying Trays and Material Racks: Used to place the materials to be dried. The drying trays are usually made of stainless steel or high - temperature resistant plastic, with uniform size specifications, which are convenient for loading, unloading and replacement. The material racks can be designed into multiple layers as needed to make full use of the drying space.

Control System: Composed of temperature sensors, humidity sensors, controllers, etc.

Dehumidification Device: Such as dehumidification fans, louver - type air outlets, etc.

Technical Parameters

| Single drying channel double-circulation dryer | |

| Overall Dimensions | 5800x2150x2200mm |

| Heat pump power | 20Hp |

| Auxiliary heating power | 18kW |

| Material Carriages | 4 carriages installed inside |

| dimensions | 1950× 800 × 1950mm. Each carriage has 15 layers, with 3 trays per layer, total 45 trays per carriage. |

| Trays dimension | 800×600×20mm.Total 45*4=180Pcs |

English

English Español

Español Français

Français Русский

Русский العربية

العربية

Welcome to send your message to us