Instruction:

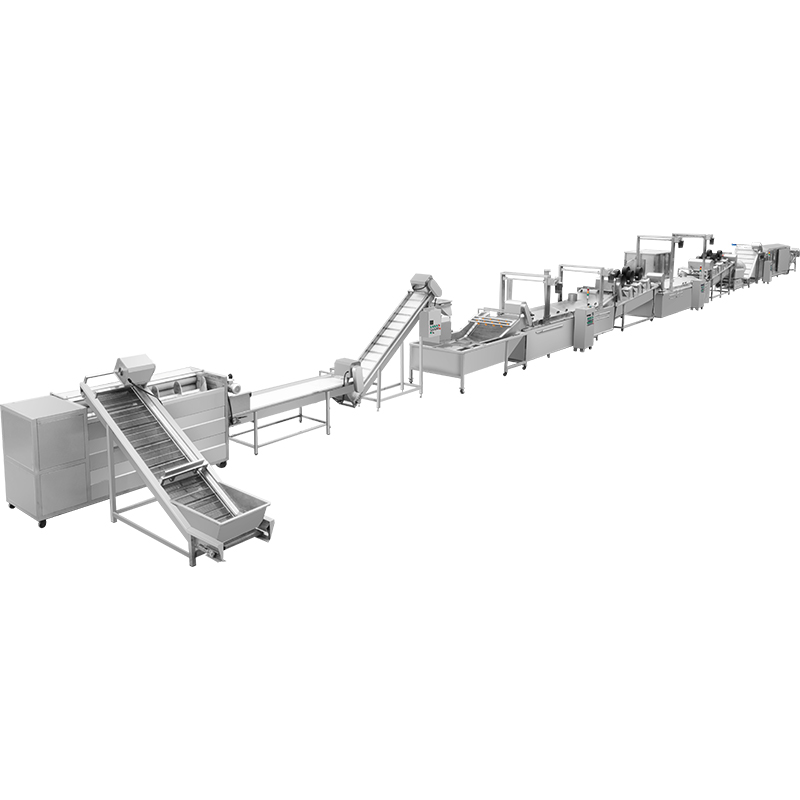

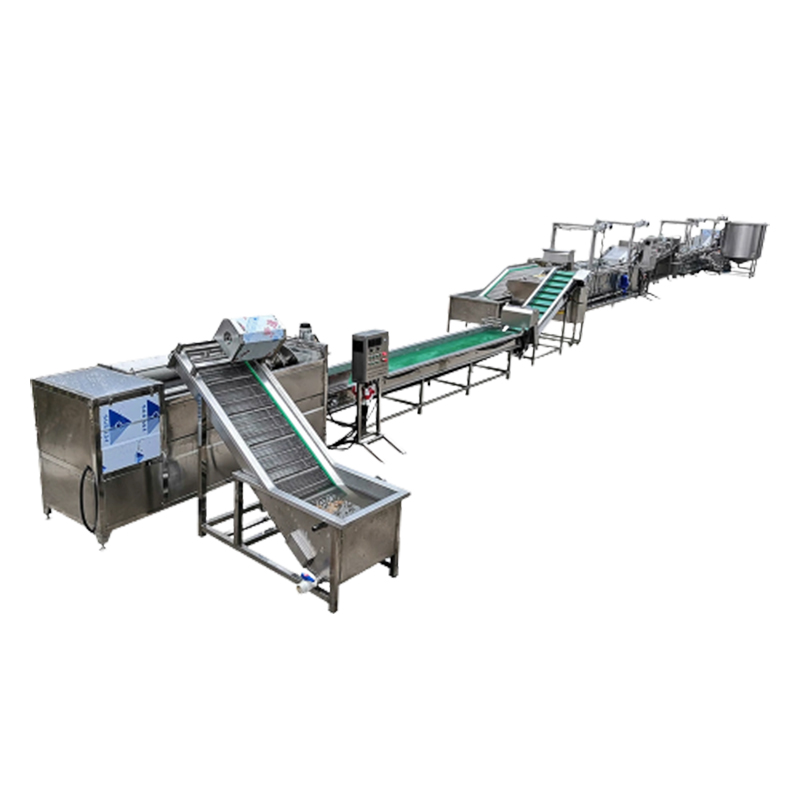

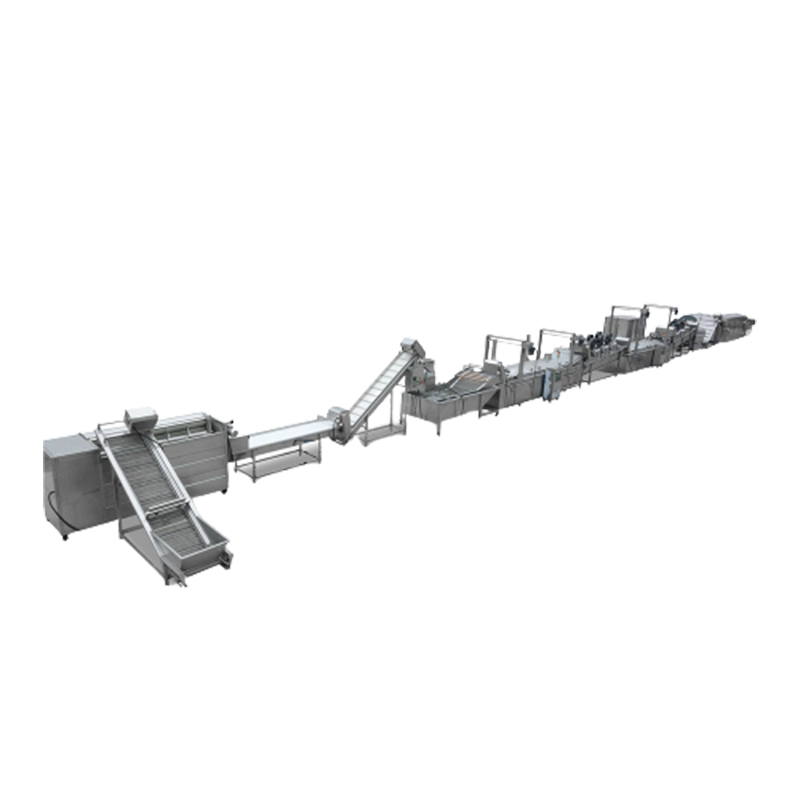

The automatic frozen French fries production line is an automated production equipment used to process potatoes into frozen French fries, enabling fully automated operations from raw materials to finished products. Here is a detailed introduction:

● Cleaning and Peeling: Use a cleaning and peeling machine, which utilizes the brush principle to clean and peel the potato skins.

● Sorting: Manually pick out defective or incompletely peeled potatoes through the sorting line.

● Cutting: Potatoes are conveyed into the strip cutter by a hoist and cut into uniform fries.

● Rinsing: The fries enter the rinsing machine, and surface impurities are removed through a bubble generating device.

● Blanching: They are sent to the blanching machine for color fixing treatment to make the fries more brightly colored.

● Cooling: After blanching, the surface temperature is quickly reduced through the cooling line to prevent over-blanching.

● Air-Drying: The surface moisture of the fries is blown off by high-pressure wind from the fan to prevent oil splashing during frying.

● Screening: Waste and substandard-sized fries are removed by a vibrating screen.

● Frying: Qualified fries are sent to the frying line, which uses electric heating to control the temperature for frying, resulting in fries with bright color and crispy taste.

● De-oiling: After frying, the surface oil is blown off by high-pressure wind from the fan to make the fries less greasy.

● Freezing: The fries enter the freezer, and the core temperature drops to -18°C in a short time to reduce nutrient loss.

● Packaging: After manually picking out unqualified products, the automatic packaging machine completes processes such as feeding, bag making, filling, and date printing.

Technical Parameters

| Capacity | 300kgs/h, 500kgs/h, 1000kgs/h, 2000kgs/h, 3000kgs/h, 5000kgs/h |

| Heating model | Electric, Gas, Diesel, LPG, Biologic pellet or Coal. |

Video

English

English Español

Español Français

Français Русский

Русский العربية

العربية

Welcome to send your message to us