-

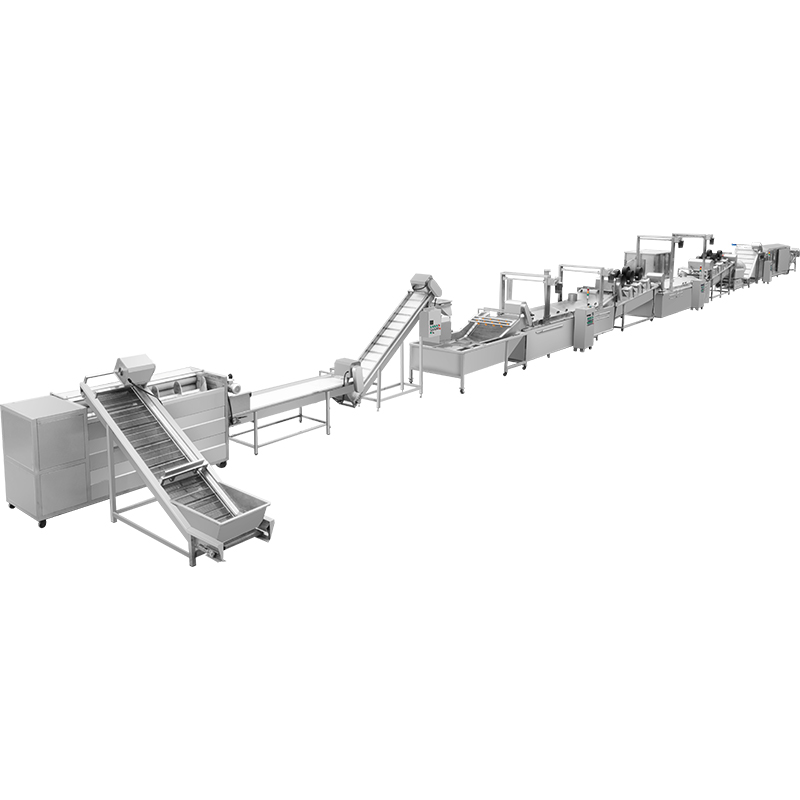

Frozen French Fries Machine

The automatic frozen French fries production line is an automated production equipment used to process potatoes into frozen French fries, enabling fully automated operations from raw materials to finished products. Here is a detailed introduction:

Details

● Cleaning and Peeling: Use a cleaning and peeling machine, which utilizes the brush principle to clean and peel the potato skins.

● Sorting: Manually pick out defective or incompletely peeled potatoes through the sorting line. -

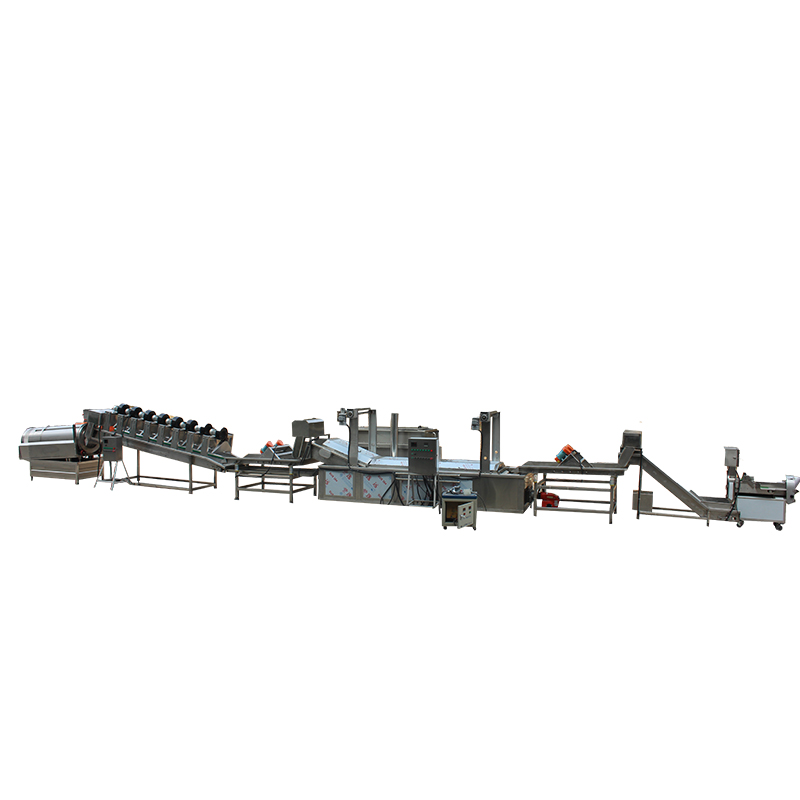

Potato Chips Frying Machine

The potato chips production line is an automated production line used to process potatoes into fried potato chips, enabling continuous operations from raw material processing to finished product packaging. Here is a detailed introduction:

● Cleaning and Peeling: Remove sediment and impurities from the surface of potatoes through a cleaning machine, then peel off the outer skin with a peeling machine (usually brush-type or steam-type).

Details -

Banana Chips Frying Machine

● Slicing: Send the banana pulp into a slicer to cut into uniform slices (generally 2-4 mm thick, adjustable according to product requirements).

● Frying: Banana slices enter a continuous fryer and are fried with vegetable oil (such as palm oil). The oil temperature (usually 160-180°C) and time are controlled to make the banana slices crispy while retaining the sweet aroma of bananas.

Details -

Snack Food Frying Machine

The snack food frying line is an automated or semi-automated production line suitable for manufacturing various small fried snacks (such as fried peanuts, dried small fish, broad beans, potato chips, rice crackers, etc.). It enables continuous processing from raw material pre-treatment to finished product packaging.

Details -

Semi Automatic Potato Chips Machine

1. Peeling: firstly, the potatoes shall be washed and peeled by the potato washing and peeling machine.

2. Cutting: the peeled potatoes are cut into strips by the super-speed slicing machine.

3. Blanching: put the potato chips into the blanching machine for inactivating the oxidase in potato chips, preventing color deterioration and accelerating dehydration.

Details

English

English Español

Español Français

Français Русский

Русский العربية

العربية

Welcome to send your message to us