Instruction:

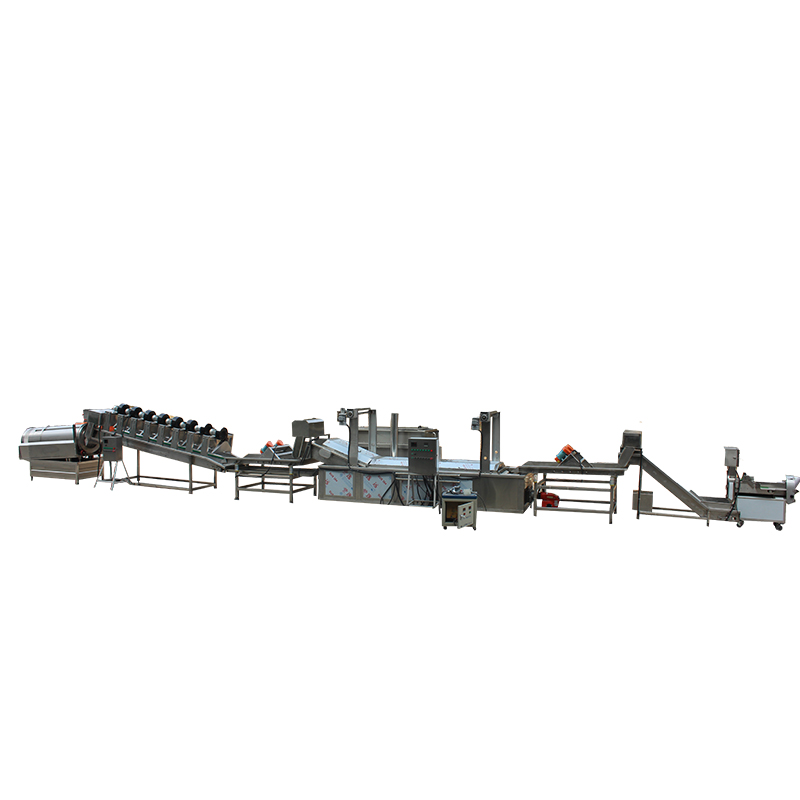

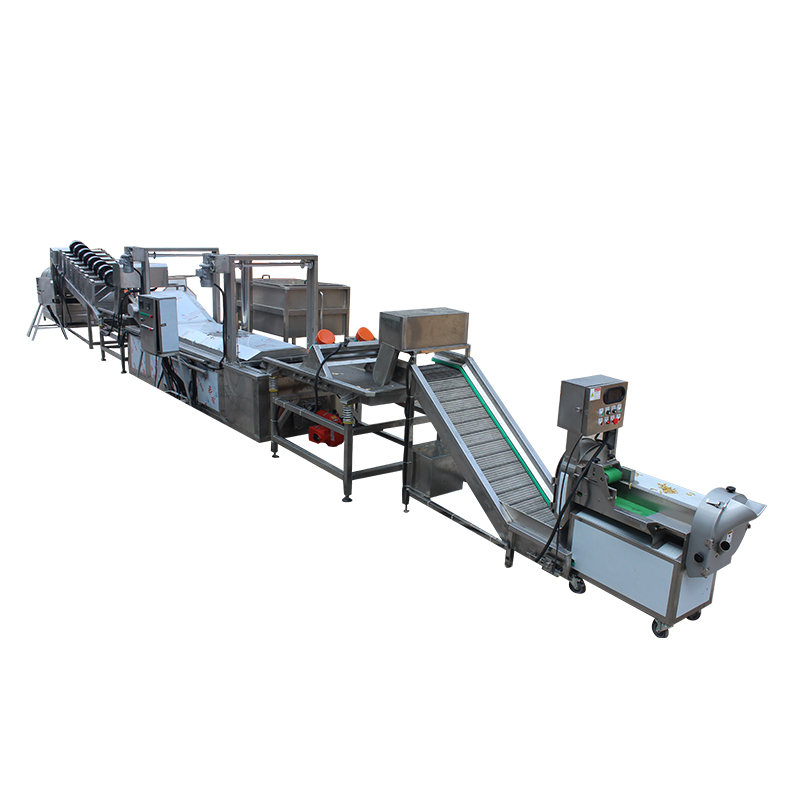

● Slicing: Send the banana pulp into a slicer to cut into uniform slices (generally 2-4 mm thick, adjustable according to product requirements).

● Frying: Banana slices enter a continuous fryer and are fried with vegetable oil (such as palm oil). The oil temperature (usually 160-180°C) and time are controlled to make the banana slices crispy while retaining the sweet aroma of bananas.

● De-oiling: After frying, excess oil on the surface of banana slices is removed by centrifugal de-oiling or air-blowing de-oiling to reduce greasiness.

● Seasoning (Optional): According to taste requirements, add seasonings such as sugar, salt, and spices through a seasoning machine to enrich the flavor of banana slices.

● Packaging: Qualified banana slices are processed by an automatic packaging machine to complete metering, bagging, sealing, date printing and other processes to make finished products.

Technical Parameters

| Capacity | 50kgs/h, 100kgs/h, 200kgs/h |

| Heating model | Electric, Gas, Diesel, LPG, Biologic pellet or Coal. |

Video

English

English Español

Español Français

Français Русский

Русский العربية

العربية

Welcome to send your message to us